Affordable Garbage Disposal Repair Houston: Preventative Care

Few appliances take more abuse than a kitchen garbage disposal. It swallows peels, stray pasta, the odd fork that slips down the drain, and all the rinsed-off grit from your cutting board. In Houston, where humidity, heavy cooking, and diverse cuisines converge, disposals see real-duty service. The good news is that most failures don’t come out of nowhere. They grow quietly through small habits, missed maintenance, and delayed fixes. With consistent preventative care and smart decisions, you can extend the life of your unit, reduce odors, and avoid emergency calls for garbage disposal repair.

Below you will find a practical approach based on hands-on experience with disposals in Houston homes and light commercial kitchens. Consider this a field guide: what to watch, what to ignore, and when to call for affordable garbage disposal repair rather than replace the unit altogether.

Why preventative care pays off in Houston kitchens

Humidity speeds corrosion. Hard water leaves mineral deposits that stiffen moving parts. And the way many of us cook — frequent frying, slow-cooker proteins, rice and beans, citrus, and tough fibrous vegetables — introduces all the materials that disposals struggle with. Every extra strain on the motor or bearings shortens the appliance’s usable life.

Two cost drivers keep showing up in service calls. First, burned-out motors from repeated overloads, often caused by grinding the wrong items or running without adequate water. Second, leaks from worn seals or cracked housings, frequently aggravated by vibration or rust. Both issues are preventable most of the time. Preventative care doesn’t mean babying your disposal. It means running it the way it was designed and tending to the warning signs early.

What a healthy disposal sounds and smells like

A well-tuned unit starts fast, hums evenly, and clears waste within a minute or so for typical use. The pitch may climb as food clears, then settle as the chamber empties. There should be no rattling, metallic clanking, or electrical buzzing. Odor should be neutral, maybe a faint clean-water scent after you flush it. If you smell sour drain gases or a stale funk, debris is sitting somewhere it shouldn’t.

Some homeowners ignore a small rattle or a sluggish spin because the sink still drains. That’s the moment to act. Early attention keeps a $20 fix from becoming a $200 repair visit.

What not to feed your disposal, and why that matters

The advice you may have heard, “It’s a grinder, it eats everything,” only holds up if you plan to replace it every year. Technically, disposals don’t use blades like a blender. They use impellers and a grind ring to mash and scrape waste into slurries. The design excels with small, soft scraps and falls short with fibrous, starchy, or dense objects.

Grease and fats coat the grind chamber and drain line, then cool into sticky films that grab more particles. Coffee grounds look harmless but settle into heavy sludge pockets. Pasta and rice swell with water and turn gluey. Corn husks and celery strands tangle around the impellers and stall the motor. Bone fragments are hit or miss: small chicken bones usually pass, beef or pork bones often don’t. Eggshells are controversial. A few now and then won’t destroy a robust unit, but they add to mineral grit that dulls the grind ring and settle in traps.

If you love crawfish boils or backyard brisket, steer those scraps to the trash or compost. Your future self will thank you when the sink drains fast after a big weekend cook.

The water rule

Every pro has a version of this rule, and it’s nonnegotiable. Run a strong, cold water stream before you flip the disposal switch. Keep it running while you grind. Let the water continue for 10 to 20 seconds after the last sound of grinding. Cold water helps solidify any stray fats so the impellers fling them out instead of smearing. It also flushes pulverized particles through the trap and down the line. Skimp on water and you’ll move the problem from the grind chamber to the section of pipe you can’t see.

The follow-up question we hear: how much water is too much? You don’t need a wide-open gusher. A steady, pencil-thick stream from the faucet usually suffices for residential units. For larger three-quarter horsepower models, go a bit stronger.

Simple monthly care that actually extends life

Most disposals die from neglect. A monthly routine makes a difference, especially in Houston’s climate. The following checklist is short on gimmicks and long on results.

- Flush the drain with cold water for a full minute after normal use, once or twice a week, even if you didn’t grind anything substantial. This clears sediment from low-flow days.

- Clean the splash guard. Pull the rubber baffle and scrub both sides with dish soap and a brush. Debris and biofilm collect there, and that’s the source of most odors.

- De-scale light mineral buildup. Pour a half cup of distilled white vinegar, wait ten minutes, then rinse with cold water while running the unit for a few seconds. Avoid leaving strong acids sitting for long periods.

- Freshen with ice and salt. A cup of ice cubes with a tablespoon of coarse salt scrubs the grind chamber safely. Do this once a month. Skip citrus peel dumps; thin peels are fine, but thick rinds can wedge in cheaper units.

- Inspect for slow seepage. Run the unit with the sink filled halfway, then drain and check under the sink with a dry paper towel along the seams and the dishwasher inlet. A damp line early on is easier to fix than an active leak later.

When a jam isn’t a failure

A jam is the most common service call for garbage disposal repair. Usually, it’s a temporary stall because an object blocked the impellers. The motor overheats, trips the internal breaker, and the unit goes silent except for a faint hum. Many homeowners can safely clear a jam without calling a pro, provided they respect a few boundaries.

Unplug the unit or flip the breaker. Never put your hand inside. Use the supplied hex wrench in the bottom center slot to rock the motor back and forth. This motion frees stuck impellers. Press the red reset button on the bottom of the unit, restore power, run cold water, and test. If you hear grinding that doesn’t clear or the reset keeps popping, call for kitchen disposal repair Houston technicians trust. Repeat resets under load can burn a weakened motor.

Objects that commonly cause jams in Houston homes: broken glass from drinkware, peach or avocado pits, metal bottle caps, and small toy parts dropped by curious kids. Knife tips and measuring spoons also show up more often than you’d think.

Odor control that isn’t perfume

Covering smells with citrus oil only delays the fix. Odor comes from films on the rubber baffle, trapped sludge in the grind chamber, or organic build-up downstream. Clean the baffle thoroughly. Run ice and salt as described above. If the smell returns within days, the P-trap or branch line likely needs cleaning. A professional can remove the trap, flush the line, and reassemble with new washers. It’s a short service call that saves weeks of frustration.

Avoid bleach. It can harden rubber, corrode metals, and create fumes in tight cabinets. Enzyme drain cleaners sometimes help for biofilm, but many are slow. If you use one, follow the label and do not mix with other chemicals.

Why units leak, and how to stop it early

Leaks rarely explode overnight unless a freeze event or a cracked housing is involved. More often, they begin as slow weeps at a gasket or joint:

- Sink flange seal: The putty between the drain flange and sink can dry out and shrink. You’ll see moisture along the top ring. Resealing with fresh plumber’s putty fixes it.

- Dishwasher inlet: The hose clamp loosens from vibration. Retighten, or replace the hose if it’s brittle.

- Discharge elbow: The outlet that connects to the drain line uses a flat gasket. Age flattens it. Swap the gasket and retighten.

- Body corrosion: On older budget units, rust can perforate the shell. If the leak comes from the body, replacement is the answer, not patching.

Lay a dry paper towel under potential leak points and run a full sink of water through the disposal to test. It’s a simple way to trace a small drip before it damages the cabinet.

Choosing repair over replacement, or vice versa

Affordability sometimes means repairing the unit you already own. Other times, emergency disposal repair it means not sinking money into a failing design. Think in terms of age, horsepower, noise level needs, and your cooking habits.

If your disposal is under five years old and the issue is a jam, loose wire, worn splash guard, or simple leak, affordable garbage disposal repair makes sense. Parts are inexpensive, and labor is modest. If the motor grinds loudly even when empty, the bearings are failing. On lower-cost models that are seven to ten years old, replacing the unit often costs less than a bearing rebuild.

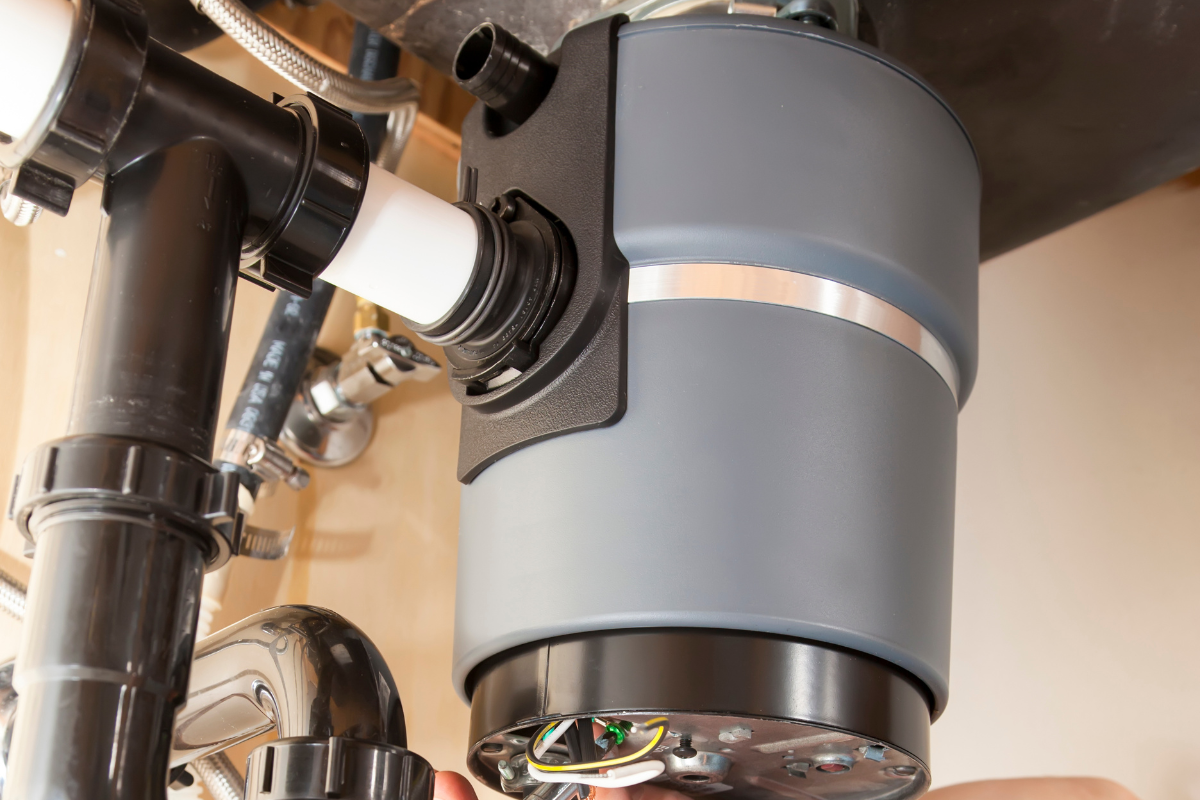

Families that cook daily and grind vegetable scraps benefit from three-quarter horsepower units with better sound insulation. Light users, like small households that mainly rinse plates, do fine with one-half horsepower. A garbage disposal installation Houston homeowner can manage by themselves is possible, but only if comfortable with electrical connections, mounting flanges, and trap alignment. A misaligned trap or loose flange erases any savings with water damage.

A Houston note on dishwashers and disposals

Many disposals share a drain line with the dishwasher. If the dishwasher backs up into the sink or the sink water gurgles into the dishwasher, there’s likely a blockage at the disposal inlet or the knock-out plug was never removed during installation. For new installs, confirm the small plastic plug inside the dishwasher inlet on the disposal has been punched out. For existing systems, clean the inlet barb and check the air gap or high loop. Houston’s building codes vary by municipality, but a high loop on the dishwasher drain hose is typically required at minimum to prevent backflow, and an air gap may be required in some jurisdictions. A pro familiar with the local code can bring you up to spec quickly.

Electrical safety you can’t skip

Disposals draw significant current at startup. A failing unit that trips breakers deserves a closer look. Heat marks on wire nuts, a soft switch that feels spongy, or frequent resets indicate an electrical issue. GFCI protection for outlets serving kitchen counters is standard. If your disposal is plugged into a GFCI and it trips when the unit starts, you might have moisture in the junction box under the sink or a ground fault inside the motor. Water and electricity don’t negotiate. Pull power and schedule service.

Homeowners sometimes wire a disposal to the same circuit as a high-draw appliance like a microwave. It works until both run at once. If lights dim when you use the disposal, have an electrician evaluate the load.

The quiet factor: sound insulation and vibration

Older or budget models can be loud enough to pause conversation. Sound matters in open-plan homes. Newer units use better insulation and balanced impellers to drop noise by a surprising margin. If vibration rattles the sink or the countertop, check the mounting ring. A slightly loose ring multiplies vibration, which then loosens screws and shortens the unit’s life. Rubber mounting gaskets also compress over time; a pro can replace them during a service visit.

Noise that suddenly increases often signals a foreign object or a grind ring chipped by a hard item like a peach pit. Removing the object sometimes solves it. If not, that roughened ring will keep the racket going and dull performance.

True costs: what “affordable” really means

Affordability isn’t just the invoice. It’s the pattern of costs over the life of the unit. A reliable half-horsepower disposal might cost less than a night out, and with good care it can last eight to ten years. Routine service for garbage disposal repair typically lands in a range that makes sense if the unit has at least two to three years of useful life left. On the other hand, throwing service dollars at a corroded, loud, underpowered unit that struggles every holiday is a false economy.

When considering garbage disposal installation Houston homeowners should factor in the time and tools. You’ll need plumber’s putty, a torque-friendly screwdriver set, a bucket for trap water, Teflon tape for threaded connections, and comfort with working under a cabinet in tight quarters. If you want set-it-and-forget-it certainty, a pro install is often cheaper in the end.

The effect of Houston’s water and climate on lifespan

Hardness varies across the metro. West and north of downtown often see higher mineral content. Scale stiffens the grind chamber and narrows drain pipes. Combine that with warm under-sink temperatures for most of the year and you have ideal conditions for slime and mineral crust. A quarterly de-scale with diluted vinegar, plus steady cold water use during grinding, offsets a lot of this. If you run a water softener, you’ll gain some lifespan in the disposal and the dishwasher, though you’ll still want to keep grease out.

Storm surges and heavy rain events can push foul air up through drains, leaving odors even in well-maintained systems. When that happens, a thorough trap cleaning and baffle scrub usually resolves the smell without deeper work.

The overlooked part: the splash guard

That soft rubber baffle at the top does more than stop splashes. It controls the flow of water and keeps debris from bouncing out. A stiff, torn, or warped splash guard reduces grinding efficiency because water doesn’t circulate well inside the chamber. It also harbors odor. Replacements cost little and snap in within minutes. If your disposal feels weaker than last year, replacing the baffle can make an immediate difference.

A few true-to-life scenarios from service calls

A Montrose condo with a single resident had a persistent sour smell, even after the disposal ran clear. The culprit wasn’t inside the unit. Coffee grounds had settled in the horizontal branch line beyond the P-trap, forming a dense layer. A simple trap removal and line flush solved it. No fancy chemicals, just mechanical cleaning and a warning against dense grounds.

A family in Katy had a unit that tripped the reset button twice a week. They fed the disposal onion skins and long celery strands from prepping family meals. Strands wrapped around the impellers and stressed the motor. Teaching the family to trash the fibrous peels and cutting long scraps short reduced jams to zero. The unit kept running strong for two more years.

A homeowner in The Heights reported a sudden loud clatter, followed by leaks. We found a coin wedged at the grind ring that had carved a groove. The shock loosened the discharge elbow. Repair would have required a new grind ring and seal kit, parts that cost nearly half a new mid-range unit. Given the age — eight years — the homeowner chose a replacement with better sound insulation. Noise dropped dramatically, and the cabinet stayed dry.

When to schedule professional service

If any of these apply, get help rather than experimenting:

- The motor hums but doesn’t spin after you’ve tried the hex wrench reset, and the reset button clicks repeatedly.

- You see water dripping from the body of the unit, not just a joint or gasket.

- There is a persistent burning smell, a sign of failing windings or bearings.

- The dishwasher repeatedly backs up into the sink even after you’ve checked the high loop or air gap.

- The unit trips a GFCI or breaker, especially after you’ve inspected and dried visible connections.

Local technicians who focus on kitchen disposal repair Houston wide have parts on hand for common brands and can turn around service quickly. Ask for a price range up front and whether the visit fee rolls into the repair cost. Clear terms keep the repair affordable.

Smart upgrades during replacement

If your unit is due for retirement, a professional garbage disposal installation Houston homeowners often choose includes two upgrades: an anti-vibration mount and a stainless steel grind chamber. The former cuts noise and cabinet wear. The latter resists corrosion better than painted steel shells. If you have a busy kitchen, consider units with auto-reverse features that reduce jams. These cost slightly more but pay back over years of fewer headaches.

For households with septic systems, pick a disposal rated for septic use. These often come with enzyme cartridges or maintain finer grind to protect the system. And always confirm that your plumber reinstalls the dishwasher drain with a proper high loop or air gap to protect against backflow.

How to keep repairs affordable without cutting corners

Independent technicians compete on price and speed, but you still want quality workmanship. Provide the model number of your unit when you call. Describe symptoms plainly: humming, grinding, leaking from the bottom, or smell. Mention what you’ve tried already. Clear info helps the tech bring the right parts and finish the job in one visit. Ask about a simple maintenance add-on while they’re on site: baffle replacement, gasket swap, and a trap clean. Bundling small tasks during one visit often costs less than calling back.

If you’re choosing between repair and replacement, ask the tech to show you the worn parts and explain the risk of continued use. Good pros will walk you through the trade-offs without pressure.

A seasonal rhythm that works

Houston kitchens run hot most of the year. Create a light seasonal rhythm around that reality. Spring and fall are good moments to do a deeper clean: pull the trap, wash it out, replace the baffle, check mounting screws, and inspect the cabinet for moisture stains or soft spots. Before holiday cooking ramps up, run a longer flush after each use and discourage guests from loading the disposal with bones or fibrous peels. Small rituals, big results.

Final thoughts from the field

Disposals aren’t glamorous, but a quiet, reliable unit keeps the kitchen moving. Most calls for garbage disposal repair stem from predictable patterns, not bad luck. Respect the water rule, control what you feed the unit, keep the splash guard clean, and pay attention to small changes. When in doubt, bring in a pro for affordable garbage disposal repair before a minor jam becomes an after-hours emergency. With a bit of preventative care and timely decisions, your sink stays clear, your cabinet stays dry, and your unit lasts years longer than the sticker says it should.

DYZ Plumbing, LLC

Address: 1220 Blalock Rd, Houston, TX 77055

Phone: (832) 877-9600